What is Swaging Machines? Types and Applications by HOREN Industrial Co. Ltd.

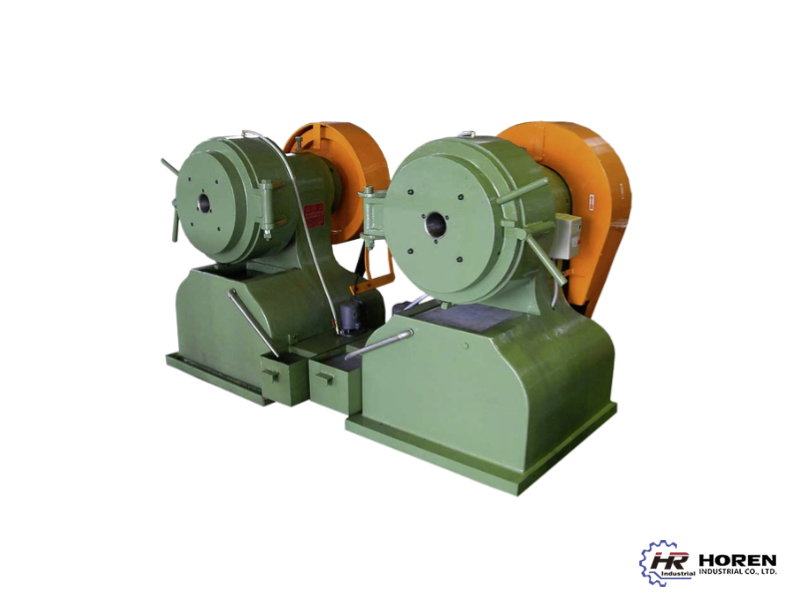

A swaging machine, also known as a swager, is a specialized tool used in the metalworking industry to form a reduction or to taper in a piece of metal, such as a rod, tube, or wire. This process, known as swaging, involves using dies that hammer or press the metal into a desired shape. Swaging machines, manufactured by HOREN Industrial Co. Ltd., can be either rotary or radial in their action, depending on the specific application and the complexity of the shape required.

Types of Swaging Machines

- Rotary Swaging: This type uses a rapidly rotating spindle and attached dies that open and close rapidly around the workpiece. As the dies impact the material, they shape it by forcing it into the gradually reducing cavity of the dies. Rotary swaging is typically used for precision work and can handle smaller, more delicate pieces like wires or small tubes. It is highly efficient and produces a smooth surface finish.

- Radial Swaging: In radial swaging, the dies impact the workpiece radially, similar to the action of a forging press. This method is typically used for larger, bulkier items and can involve either cold or hot working processes. Radial swaging is often used for items like aircraft landing gear, automotive parts, or large industrial components.

Applications of Swaging Machines

Swaging machines are used in various industries, including aerospace, automotive, and construction, for a range of applications:

- Aerospace and Automotive: Producing components like cables, rods, and tubes that require precise dimensions and high strength-to-weight ratios.

- Construction: Making bolts, rivets, and similar fasteners used in building structures.

- Electrical: Manufacturing connectors and terminals for electrical wiring systems.

- Medical: Creating components for medical devices, such as dental and orthopedic implants that require small, precisely shaped metal parts.

How to Select the Right Swaging Machine by HOREN Industrial Co. Ltd.

HOREN Industrial Co. Ltd. offers a range of swaging machines with motor capacities labeled in horsepower (HP). Here's how to choose the right model:

- Assess the Material Type and Size: Different materials and sizes require different horsepower and speeds for effective processing.

- Production Speed Requirements: For high volume or fast-paced production, opt for a machine with higher horsepower to maintain efficiency.

- Accuracy and Surface Quality Needs: Some high-precision applications might require running at specific speeds to achieve the best surface finishes.

- Energy Efficiency and Cost: Higher horsepower machines consume more energy, which can affect operational costs. Choose based on your budget and energy efficiency needs.

- Space and Installation Constraints: Ensure there is enough space to install and maintain the machine, as the size and setup requirements vary.

By considering these factors, you can select a swaging machine that best fits your company's needs, ensuring optimal performance and product quality. HOREN Industrial Co. Ltd. is committed to providing top-tier metalworking solutions that meet the demands of a diverse industrial clientele.