What is automatic cold drawing machine and how it works?

What is automatic cold drawing machine?

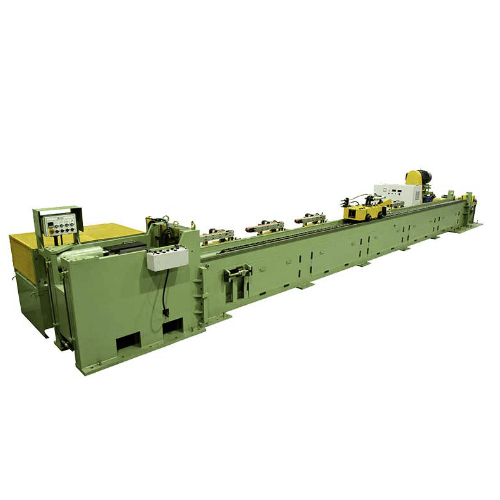

The Automatic Cold Drawing machine manufactured by HOREN is a chain-type machine which has equipped with a loading machine, feeding machine, hydraulic push pointer, and drawbench with discharging arms attached. The HS model series is designed to streamline the cold drawing process by using a hydraulically powered extrusion unit (also known as the push pointer) to clamp the workpiece and push it directly against the drawing die. Brass, mild steel and alloy bars are the most common materials to be used on this machine. The drawn materials are then carried using discharing arms to designated collection racks next to the drawbench.

HOREN's automatic bar-to-bar cold drawing machine was initially developed to draw hexagonal carbon steel bars for screws and nuts with a push pointer. The versatile design of heavy-duty models is later used to draw linear guideways and other symmetrical alloys. From loading to discharing, this entire process is using a PLC system, making it very efficient and ideal for automatic bar-to-bar drawing. The head-press mechanism replaces the swaging process that is normally required during traditional cold drawing. The fully automated process reduces the need for costly manpower and helps to streamline the precision drawing process. The automation from our HS model series is suitable for the drawing of round, hexagonal, and square metal bars.

What is a cold drawing machine, also known as a cold drawing bench, is a machine used to cold draw or cold work metal wires, rods, and tubes to improve their mechanical properties and dimensions. The process of cold drawing involves pulling a metal rod or wire through a series of dies of decreasing size, with each pass reducing the diameter and improving the surface finish of the material.

What is cold drawing machine?

The cold drawing process is typically used to produce high-quality, precision-sized metal products with improved surface finish, strength, and ductility. It is commonly used in the production of steel wire and tubing used in various applications, including automotive parts, construction materials, and medical devices.

Cold drawing machines come in a variety of sizes and configurations depending on the specific application and type of material being processed. They may be manually operated or fully automated and may use various methods to draw the material, including single-pass or multiple-pass drawing. The machines may also include various additional equipment, such as cleaning, lubrication, and cooling systems, to optimize the drawing process and improve the quality of the finished product.

How cold drawing machine work?

A cold drawing machine works by pulling a metal rod or wire through a series of dies of decreasing size. The dies are typically made of hardened steel and are designed to progressively reduce the diameter of the material being drawn.

The process begins with a metal rod or wire that has been prepped by cleaning and straightening. The material is then fed into the drawing machine, where it is clamped securely and passed through the die. The die reduces the diameter of the material, and this process is repeated until the material reaches the desired diameter.

As the material is pulled through the dies, it undergoes deformation, which causes the grain structure of the metal to be refined, resulting in improved mechanical properties such as increased tensile strength and improved surface finish. The process can be repeated several times, with each pass further refining the material.

Cold drawing machines can be configured for single-pass or multiple-pass drawing, depending on the desired final diameter and properties of the material. Additional equipment such as lubrication and cooling systems may also be used to optimize the drawing process and improve the quality of the finished product.

How to choose a quality automatic cold drawing machine?

When it comes to selecting an automatic cold drawing machine, there are several key factors that one must consider. It is essential to choose a reliable and well-performing machine that can effectively meet your production needs and ensure the highest quality of output.

First and foremost, it is necessary to evaluate the technical specifications of the machine. The machine should have a strong draw bench and the ability to handle various types of wire and tubing materials. The draw bench should be able to produce a wide range of diameters with high precision and consistency. Additionally, the machine should have a mechanism for adjusting the diameter of the dies in order to accommodate different thicknesses.

Another important aspect to consider is the machine's efficiency and speed. The machine should be designed to operate efficiently, with minimal downtime and maintenance. This means that the machine should be equipped with high-quality components and advanced software to optimize the drawing operation. It should also be able to process a large volume of wire in a short amount of time, without compromising on quality.

The safety features of the machine are also crucial. It is essential that the machine is designed with safety in mind, with safety guards and automatic shut-off systems to prevent accidents and injuries. It should also be equipped with emergency-stop buttons, safety interlocks, and other safety devices.

Moreover, the level of automation in the machine should also be considered. A good automatic cold drawing machine should have a high degree of automation, with intuitive control systems and advanced software that allow for easy adjustments and monitoring of the drawing process. This not only makes the machine more efficient but also reduces the need for operator intervention and reduces the likelihood of errors.

Lastly, it is important to consider the reputation and experience of the manufacturer. A reputable manufacturer with a track record of producing high-quality automatic cold drawing machines is more likely to produce a reliable and durable machine that will meet your production needs effectively.

Overall, choosing a good automatic cold drawing machine involves evaluating technical specifications, efficiency, safety features, level of automation, and the manufacturer's reputation. With careful consideration of these factors, you can find a machine that will improve your production processes and enhance your overall output quality.

Conclusion

Overall, the cold drawing process is a highly controlled and precise method of refining metal materials, resulting in high-quality, precision-sized products with improved mechanical properties and surface finish. If you have any questions regarding to cold drawing machines, please feel free to contact us HOREN, we are the expert manufacturer of automatic cold drawing machines.