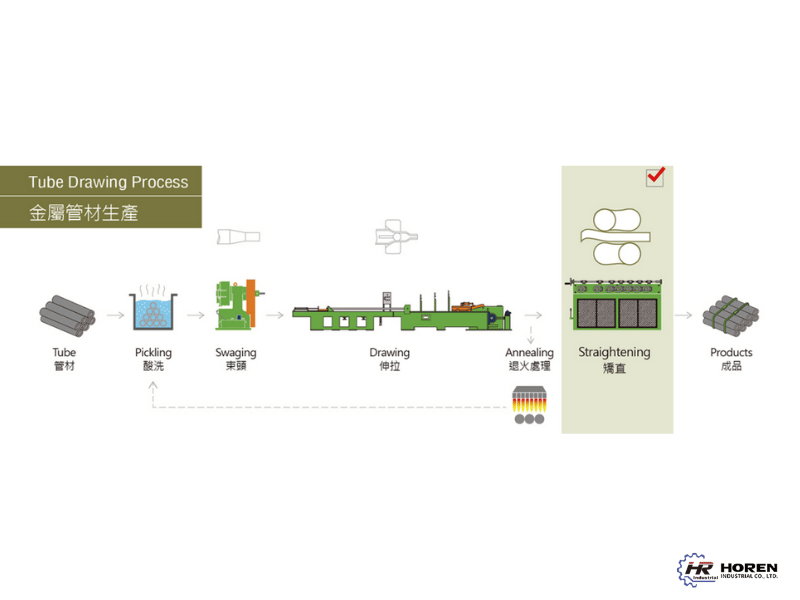

Enhancing Metal Tubing Production: Advanced Processes and Their Applications

Metal tubing is integral to numerous sectors, providing essential components that must meet strict specifications for quality and durability. At Horen Industrial Co. Ltd., our advanced production processes ensure that each piece of tubing meets these demands. Here's an expanded look into each stage of the metal tubing production process, detailing how we optimize every step to produce superior products.

In-Depth Production Stages

Pickling:

- Purpose: Cleans and prepares the metal surface by removing impurities such as rust, scale, and other contaminants.

- Process: The metal is immersed in a bath of pickle liquor, usually a strong acid, to cleanse it thoroughly before it moves to the next stage of production. This ensures that the metal's surface is pristine, which is crucial for maintaining quality in subsequent processes.

Swaging:

- Purpose: Reduces the diameter of the tube and refines the metal structure.

- Process: Using our precision swaging machines, the tubing is compressed and shaped through dies to achieve the desired diameter and contour. This stage is vital for adjusting the mechanical properties of the tube, enhancing its strength and consistency.

Drawing:

- Purpose: Refines the dimensions and improves the mechanical properties of the tubing.

- Process: Cold drawing through our advanced machinery ensures precise control over the tube's dimensions. The drawing process elongates the tube, reducing its cross-sectional area and improving tensile strength and surface finish.

Annealing:

- Purpose: Softens the metal, improving its ductility and decreasing its hardness, making it more workable for future applications.

- Process: The tubes are heated to a specific temperature and then cooled under controlled conditions. This heat treatment relieves internal stresses and realigns the metal's grain structure, which is essential for enhancing its malleability.

Straightening:

- Purpose: Corrects any distortions in the tubing, ensuring perfect alignment and uniformity.

- Process: Our multi roller straightening machines apply precise forces across multiple points along the tube's length, meticulously correcting any bends or twists to ensure that each tube is perfectly straight.

Broad Applications

Metal tubes manufactured using these processes are pivotal in various industries:

- Automotive: Employed in critical systems such as braking, fuel, and exhausts.

- Aerospace: Utilized in structural components and hydraulic systems that demand high strength and low weight.

- Construction: Integral in plumbing, HVAC systems, and structural frameworks.

- Energy: Essential in oil and gas for durable pipelines and drilling components.

Conclusion

By utilizing Horen Industrial Co. Ltd.'s advanced production technologies, manufacturers can be assured of the highest quality metal tubing designed to meet rigorous industry standards. We invite manufacturers to partner with us, leveraging our state-of-the-art equipment and extensive expertise to enhance both their product quality and production efficiency. Visit our website or contact us today to discuss how we can support your manufacturing needs with our cutting-edge solutions.

This comprehensive approach ensures that Horen Industrial Co. Ltd. not only meets but exceeds the expectations of industries reliant on high-quality metal tubing.