The Impact of Material Science on Straightening Machine Operations

In the realm of manufacturing, the materials used—be it steel, aluminum, or titanium—play a pivotal role in determining the operational parameters of straightening machines. These materials, each with unique properties such as hardness, elasticity, and ductility, significantly influence the choice and functioning of straightening equipment.

Understanding Material Properties

- Steel, known for its high tensile strength and durability, often requires robust straightening machines that can exert considerable force without compromising the material's integrity. The high hardness level of steel means that the straightening process must be precise to avoid inducing cracks or other structural failures.

- Aluminum, lighter and more pliable than steel, necessitates a different approach. Machines designed for aluminum need to account for its lower yield strength and higher elasticity to prevent over-straightening and material warping, which can lead to functional and aesthetic defects.

- Titanium, with its high strength-to-weight ratio and corrosion resistance, is particularly challenging. Straightening titanium requires machines that can provide high force while maintaining precise control to avoid stress concentrations that could lead to material failure.

Technological Adaptations in Straightening Machines

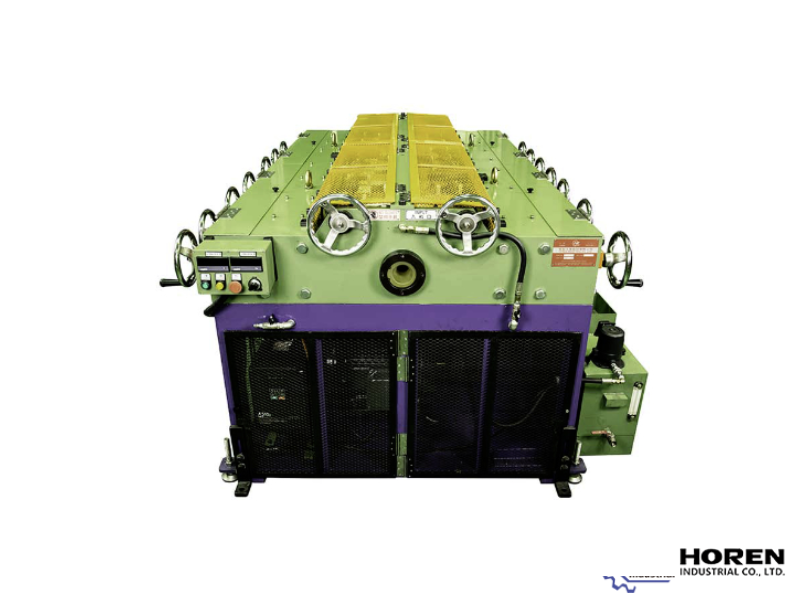

Modern straightening machines integrate advanced sensors and feedback systems to adjust the straightening process dynamically based on real-time data on material behavior. This technology is crucial for materials like titanium and high-strength steel alloys, where the margin for error is minimal.

Industry-Specific Applications

The aerospace industry, which frequently uses titanium and high-strength alloys, benefits greatly from these advancements in straightening technology. Similarly, automotive manufacturers leverage these technologies to ensure the structural integrity and reliability of steel and aluminum components, which are fundamental to vehicle safety and performance.

Conclusion

As material science continues to evolve, so too must the technology of straightening machines. Understanding the material-specific requirements and advancements in machine design is essential for manufacturers to maintain efficiency and quality in their production lines. This symbiosis between material science and machinery technology not only enhances production capabilities but also propels industries towards innovative manufacturing solutions.